Listen to this Article

Increased throughput, higher quality, and lower costs are key drivers for automated inspection in manufacturing. Manual inspection can be slow, prone to errors, and often impossible considering the product size, lighting conditions, or line speed. Most manufacturers use automated machine vision because it’s more well-suited to repetitive inspection tasks. Machine vision is faster, more objective, and works continuously. Systems can inspect hundreds or even thousands of parts per minute, and provide more consistent and reliable inspection results--24 hours a day, 7 days a week. Machine vision can also collect data for process control and improvement downstream.

So while the business need for machine vision may not be a tough decision, selecting the correct components for a machine vision platform can be. Choosing the right machine vision platform generally depends on the application’s requirements, including development environment, capability, architecture, and cost. Machine vision implementation platforms can vary, including PC-based systems, vision controllers designed for 3D and multi-camera 2D applications, standalone vision systems, simple vision sensors, and image-based barcode readers.

In this series, we’ll be exploring the many components of a machine vision system—from lighting, lenses, image sensors, controllers, vision tools, and communications protocols—to help buyers make an informed choice.

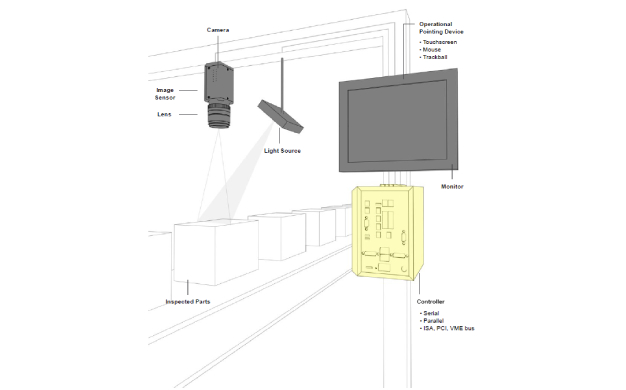

Lighting: Illuminates the part being inspected, allowing its features to stand out so they can be clearly seen by camera.

Lens: Captures the image and presents it to the sensor in the form of light.

Image sensor: Converts light into a digital image which is then sent to the processor for analysis.

Vision Processing Tools: Processes and optimizes an image for analysis; reviews the image and extracts required information; uses algorithms to run the necessary inspection and make a related decision.

Communications: A discrete I/O signal or data sent over a serial connection to a device that is either logging information or using it.

Most machine vision hardware components, such as lighting modules, sensors, and processors are available commercial off-the-shelf (COTS). Machine vision systems can be assembled from COTS, or purchased as an integrated system with all components in a single device.

Cognex offers components and integrated systems to meet any end-user, OEM, or system integrators’ needs.

Also Read: SWIR Microscopy: At The Forefront of Next Generation Technologies

Back to All Robotics and Autonomous Systems Articles, Resources and News

Share This:

For more information on Cognex Machine Vision Systems India Contact us at MVAsia Infomatrix Pte Ltd +65 6329-6431 or Email us at info@mvasiaonline.com

Source - cognex.com