Listen to this Article

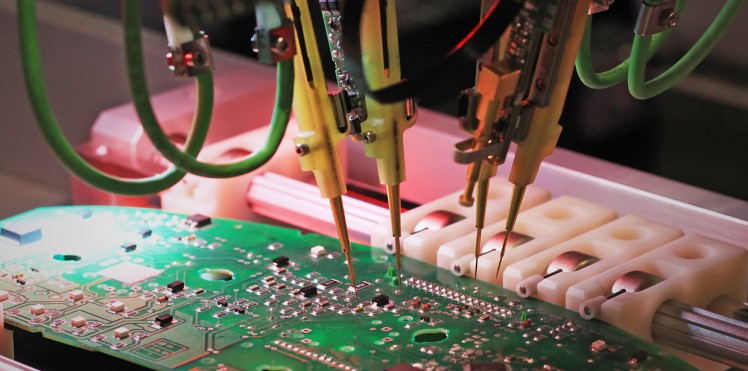

Have you ever considered how machine vision technology has transformed automated inspection? Advancements in machine vision technology significantly impact the efficiency and quality of inspections. These systems monitor material appearance and identify defects based on similarity in contrast, texture, and geometry using statistical analysis.

Machine Vision Technology Basics

In inspection settings, machine vision systems typically require the following

components:

● Lighting. Lighting illuminates the object or scene to make its features

visible.

● Lens. The lens captures the image and delivers it to the sensor in the

camera as light. Deciding on the right lens for a machine vision

application calls for a review of the required specs, some math, and a

consideration of how the lens will integrate with the camera setup.

● Capture board, frame grabber, or sensor work together to process the

image from the camera and convert it to a digital format. Image sensors

convert light into electric signals as pixels.

● Processor. The processor executes software and algorithms that

analyze a digital image and extract required information.

● Communication. These systems allow the machine vision cameras and

processing system to communicate with other more significant system

components via a digital input/output signal or a serial connection

Manufacturing

Machine vision inspection technology has transformed several manufacturing sectors. One of this technology's most significant impacts is on quality control processes. By enabling automated inspection and analysis of products, Machine Vision has dramatically enhanced the accuracy, consistency, and speed of quality control, resulting in improved production efficiency and reduced costs. By detecting issues early on, manufacturers can handle them before they cause significant problems, reducing the risk of product recalls.

Healthcare

In healthcare, machine vision technology inspects and analyzes medical images, such as X-rays or MRIs, to identify abnormalities that may indicate disease or injury. Advanced systems use sophisticated algorithms and deep learning techniques to process medical images and highlight potential areas of concern. The analysis performed by machine vision technology is highly accurate and consistent, allowing healthcare professionals to make informed decisions about the diagnosis and treatment of their patients. This technology has revolutionized how medical imaging is used in healthcare, providing a faster and more accurate way to detect abnormalities and ultimately improve patient outcomes.

Transportation

Machine vision technology is essential for inspecting and maintaining vehicles, tracks, and infrastructure in the transportation industry. Machine vision systems use cameras and sensors to capture images and data, which are then analyzed by powerful algorithms to detect defects, damage, or wear and tear. This technology helps transportation companies identify and fix issues quickly, ensuring the safety and reliability of their equipment. Machine vision technology is also used for traffic monitoring and control, making it an indispensable tool for the transportation sector.

Energy Efficiency and Sustainability

Automating inspection processes can bring numerous benefits in promoting

energy efficiency and sustainability. By removing the need for manual labor

and human intervention, automation can help streamline and optimize the

inspection process. This can result in significant time and cost savings for

businesses and increased accuracy and reliability in identifying energy

inefficiencies or other sustainability concerns. Real-time quality control not

only improves overall product quality but also reduces waste and the need for

rework. By addressing these issues, businesses can take steps towards

reducing their energy consumption and carbon footprint and contributing to a

more sustainable future for the planet.

Machine vision technology has revolutionized automated inspection in multiple

industries, increasing efficiency, accuracy, and cost-effectiveness. In most

cases, automating the inspection process is faster and more accurate than

doing it manually. As a result, many industries have embraced machine vision

technology, making it an essential component of their operations.

When selecting a lens for a machine vision application, it is crucial to carefully

evaluate the required specifications, conduct appropriate calculations, and

consider how the lens will interact with the camera setup. Choosing a great

lens tailored to your system’s needs can be daunting, but that is what we’re

here for.Talk to a lens specialist at Computar today and find out how we can

assist in selecting the correct lens for you, or view our recorded webinar "The

Impact of Machine Vision Technology on Automated Inspection."

Source: computar.com

Also Read: The Unbreakable Eye: Exploring Ruggedized Machine Vision Lenses

Back to All Robotics and Autonomous Systems Articles, Resources and News