Listen to this Article

As a business scales up in size and quantity of assets, challenges in sufficiently covering every potential point of failure can increase. A bigger building means a greater area to properly insulate and protect from water damage; more equipment means electrical systems run harder and increases the chance of system failure. Many potential failure points can be caught early and repaired though through the help of regular thermal scans and a professional thermographer.

Infrared Imaging Solutions, better known as IRIS, is an inspection firm based in Canada that operates coast to coast across North America. The firm has a team of eight thermographers, all certified as Level II or Level III thermographers by the Infrared Training Center, who are equipped with FLIR T1020s, FLIR T865s, and various other FLIR thermal imaging cameras to perform inspections. Brian Jastrow, the company’s principal owner, shared with us some of the benefits of regular thermal inspections that he’s noticed from the seventeen thousand inspections his company has performed in over twenty years in operation.

Extending a Roofs Lifespan

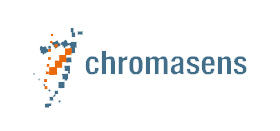

Keeping moisture outside is important for any building but especially for commercial facilities where a compromised structure would affect production. When laying down the waterproofing membrane, professionals must be confident that there’s no moisture left on the roof as it will not only be difficult to remove, but also cause expensive damage and shorten the roof’s lifespan.

IRIS’s typical commercial roof customer is a warehouse, hospital, distribution center, or other large building owner with one hundred thousand to one million square feet of roof. When it’s time for a roof’s regular checkup, thermal scans quickly locate any unwanted moisture and can verify the health of the building. Weather can be a particular problem: for example, Jastrow tells us that due to weather conditions, a roof in Ontario, Canada will typically last only twenty to twenty-five years before needing service. By using thermal scans, though, a business could significantly extend the life of a roof before needing to do any big repairs.

“At $12 a square foot for a million square feet, that’s $12 million on your roof,” Jastrow explains. “You can push (repairs) back five or ten years with a thermal scan that’s only $0.02 a square foot. You can budget four or five years in advance with thermal.”

Maintaining Energy Efficiency

Regular inspections can additionally help maintain a building’s energy efficiency and preserve the property’s value. Thermographers at IRIS frequently perform scans on high-rise buildings to ensure windows are in good shape and their glazing is holding up. Without regular checkups, window seals can breakdown and fail over time due to weather and environmental contamination, leading to HVAC systems running harder and raising energy bills.

Ensuring energy compliance can also help buildings maintain eco-friendly certifications. IRIS frequently helps real estate owners achieve certification for Leadership in Energy and Environmental Design (LEED) in Canada, a program that aims to prioritize sustainable building practices. Thermographic scans—one of the requirements for certification—ensure a building is running efficiently and even increases the property’s value per square foot.

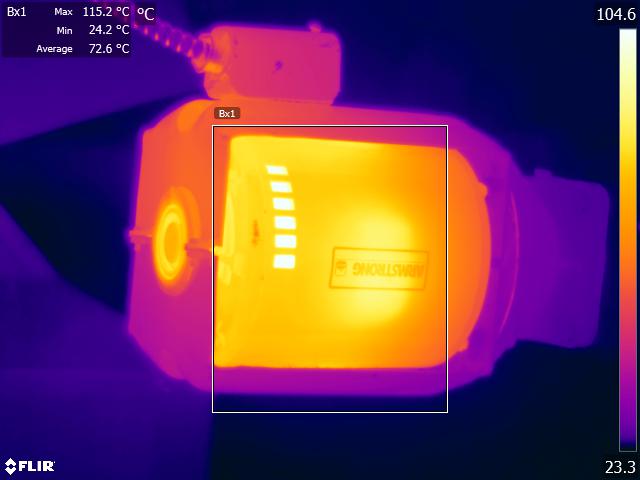

Preventing Production Shutdown and Electrical Failure

Shutdowns at manufacturing facilities compound costs in multiple ways; delayed product, work stoppage, and costly equipment repairs. Thermal scans thankfully allow businesses to avoid downtime and repair issues before they compound into other problems. “If you have an electrical failure or a refractory failure at a steel mill, you could have up to 3000 guys downstream sitting there doing nothing and that's a huge hourly cost,” Jastrow says.

Maintenance teams will typically make regular checks on equipment to ensure electrical connections are tight and machinery is operating correctly. However, unwanted heat could still be running through a faulty connection or loose component—even though it seems repaired. Thermography firms such as IRIS can help companies verify the presence of these faults and confirm that repairs have been successful. Jastrow says the process is straightforward. “We'll find the problems, they can have their electrician come in, repair a switch, and then we’ll will go back in after the repair is done with another thermal scan to make sure it was repaired properly,” he explains.

Residential real estate owners also need care for their electrical systems as much as a manufacturing facility does. When power is disrupted, owners not only need to be concerned with the cost of repairs but also the tenants without electricity. In the worst-case scenario, a faulty electrical system could even start a fire that puts lives in danger, cause expensive damage, and get a building labeled as “high-risk” from insurance companies. Yearly inspections can help real estate owners avoid dire power outages, keep occupants satisfied, and know that their building is safe.

“With our residential owners, it’s just the peace of mind that makes them want to do that yearly inspection and to ensure that their electrical system is running the way it should,” Jastrow says.

Facility managers and real estate owners have plenty to worry about when it comes to managing repairs and maintaining their investments. Yearly thermal inspections from companies such as IRIS provide peace of mind that electrical systems and machinery are working properly, energy is being used efficiently, avoid the fallout of unwanted moisture, and more.

Source: flir.in

Also Read: GETTING OGI LEAK DETECTION RIGHT WITH IMPROVED TECH AND TOOLS

Back to All Robotics and Autonomous Systems Articles, Resources and News